What are the Top Design Considerations for Cosmetic Packaging?

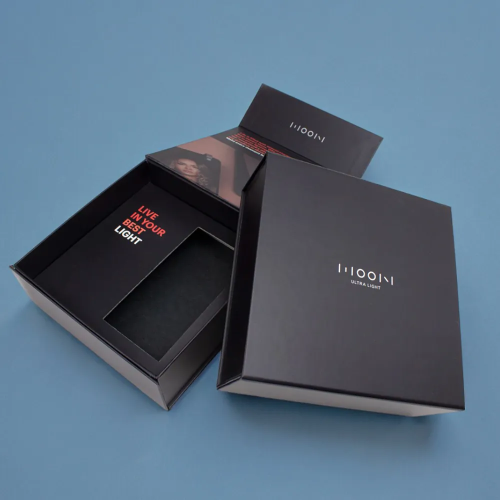

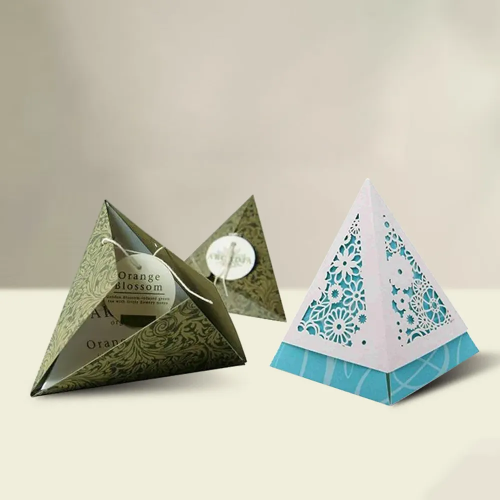

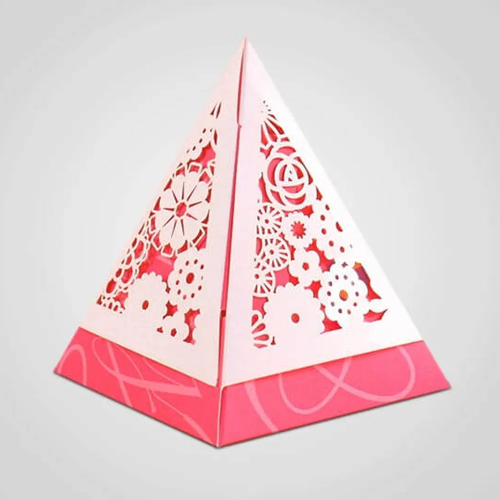

As the beauty industry is closely related to aesthetics, products in various categories must also be well-maintained from that perspective. Our manufacturing facility's entire process for Cosmetic Packaging begins with a meticulously balanced approach that combines aesthetic values, high-end functionality, and a detailed design process. All this will help boost and balance your product's efficiency, enabling it to adjust more easily to the target market. We mainly focus on fonts, typography, colour choice, box shape, and design style. At the same time, we ensure that all these elements fully define the core aspects of your branding. These design and styling efforts would be wasted if we did not combine them with top-notch printing and high-quality material selection.

For your convenience, we maintain a comprehensive selection of materials in-house. That will save you time in stock selection and quality assurance, as we choose only top-class materials to meet our clientele's requirements. We primarily use lightweight yet durable cardboard stock that is print-friendly and can be easily modified into various box styles and structures. Along with that, we also focus on the sustainability aspect of your solutions, as most of the clients these days prefer products that come in Eco-Friendly solutions. Due to our inclination towards green practices, we also offer a range of Cosmetic Packaging made from biodegradable materials. That way, we not only meet your product requirements but also fulfil the sustainability goals of your target audience.

How is Printing Executed for Quality Cosmetic Boxes Manufacturing in London, UK?

The printing process for Cosmetic Boxes is the process of transposing the design approved into physical packaging using high-quality materials. This process starts by choosing the best printing technique based on the packaging material as well as the required quality of finish. Screen printing is a common method for glass durability and tubes made of plastic, as well as digital printing for shorter-run or customised pieces. Printing plates are prepared by manufacturers or digital files that align with each method, and then colour matching is conducted to guarantee uniformity of the brand. Inks need to resist smudging, dissolving, or fading when exposed to oils or moisture. Specialised coatings and inks, such as metal foils, spot UV, and embossing, enhance the appeal of the shelf and increase brand recognition.

In addition to that, we also guarantee exact quality control. It is impossible to get the best printing or layout without it. Our facility in-house has modern design and printing layout equipment for this reason. This way, we can guarantee consistency in quality for large amounts of cosmetic boxes. In addition, we also grant the option to fully participate in the process of designing and layout. You are free to interact directly with the designers and even alter the layout of the product and box design. Our experts review the samples of each batch to ensure colour accuracy and adhesion. Following printing, packaging can undergo additional processes like coating or lamination for additional protection and aesthetic improvement. It is also possible to incorporate innovative technologies such as QR codes or RFID tags. In this way, you will have greater control over the management of your inventory.

Dimension (L + W + H) All Custom Sizes & Shapes

Quantities Minimum Order Quantity

Stock Cupboard / Rigid / Kraft / Corrugated / MOPP / PET / PE

Printing Offset / Gravure / Digital

Finishing Gloss / Matt / Soft Touch / Aqueous / Satin

Included Options Die Cutting, Gluing, Scored,Perforation

Additional Options Eco-Friendly, Recycled Boxes, Biodegradable

Proof Flat View, 3D Mock-up, Physical Sampling (On request)

Turnaround 6-8 Business Days

Shipping Flat & Assembled