What is the reason for the 1-2-3 Bottom Box Popularity?

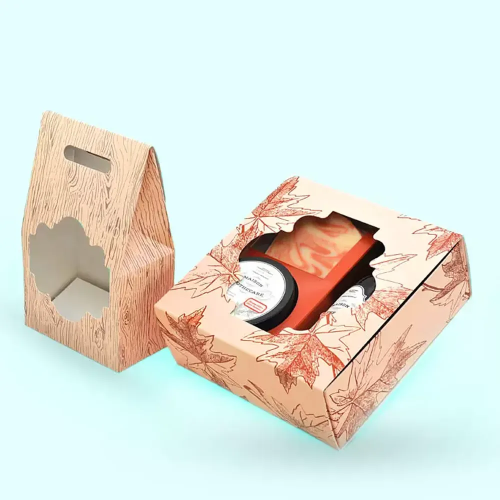

They are much appreciated because of their resilient structure and convenient use, while ensuring the items' unbreakability at the target places. Any type of items, from lighter to weightier items, can be stored and delivered in this box without any fear of destruction. The 1-2-3 Bottom Box is termed so because of the three-step requirement to close the box at the bottom. This unique locking system also provides additional robustness and protection.

They are not made using just any sort of low-profile substances; on the other hand, they are manufactured using shock-bearing substances to ensure perfect protection for the inside components. Therefore, they are frequently used by companies doing business in various areas of life, and particularly, they are unavoidable in food-serving and medicinal-related companies without any fear of impairment. They are also fairly used by electronics-related companies, and these boxes are a favourite option for showcasing in general shops. The good news is that they can be put together easily without asking for pastes or similar taping alternatives.

How is the 1-2-3 Bottom Box Useful for your Company?

As it offers customisable options to a large extent, it has shown the capability to go above and beyond to meet any company’s requirements, simultaneously providing innumerable advertising opportunities for promoting their content. Furthermore, the 1-2-3- Bottom Box can be altered by considering several imprinting options to elevate the consumer experience, while endorsing the company’s image.

They are considered invaluable for showcasing products in an online or offline store while providing the convenience and comfort of delivering products without any concern of getting destroyed while the enclosed products are on their way to delivery. As they consume less space while storing or while shipment, they are an excellent way to save money without hindering daily chores. Nowadays, manufacturers are using decomposable substances for their preparation, thus simultaneously fulfilling the requirements of a broad audience.

Dimension (L + W + H) All Custom Sizes & Shapes

Quantities Minimum Order Quantity

Stock Cupboard / Rigid / Kraft / Corrugated / MOPP / PET / PE

Printing Offset / Gravure / Digital

Finishing Gloss / Matt / Soft Touch / Aqueous / Satin

Included Options Die Cutting, Gluing, Scored,Perforation

Additional Options Eco-Friendly, Recycled Boxes, Biodegradable

Proof Flat View, 3D Mock-up, Physical Sampling (On request)

Turnaround 6-8 Business Days

Shipping Flat & Assembled