How to Optimise Coaster Packaging Designs?

Custom Designs: Coaster Packaging shapes and functions are important aspects in product positioning and product usage. Corrugated boards are characterised by partitions that allow easier shelving of goods on shelves. Corrugated boards contain micro flute surface partitions used to arrange items safely on shelves while simultaneously protecting coasters against scratch damage during transport; custom slotted tab closures add visual interest while creating uniqueness within each package design.

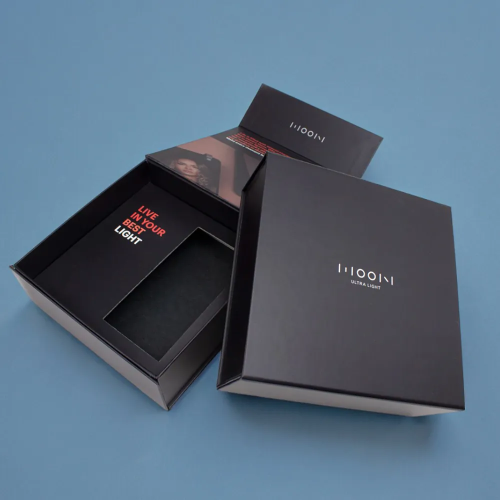

The simple and practical design in Coaster Packaging could be further enhanced in subsequent manufacturing and finishing processes so that the end customer can enjoy a fun time while using the packaging, while also preserving the items inside. The liquid coatings are also superior to other forms of cover since they are cheaper and provide resistance to abrasion and scratches, and are resistant to dampness on printed surfaces applied in beverage containers. In order to convey the softness of the product, it is possible to use soft touch lamination to give the material, including coaster boxes, a suede appearance and feel, according to which the customers can easily associate it with luxury products. The Spot UV varnish is applied selectively to give high gloss, whereas the other areas of the design can be of a flat matte appearance. This actually pulls readers to the point of convergence, say on logos. Moreover, the hot foil stamping adds metal foil, such as gold, silver, or Holographic effects on the surface of the material and illuminates under normal light, indicating the standard of quality.

Highly Convenient and User-Friendly Coaster Boxes

We'd like to know what material is best for the production of Coaster Boxes, since it will give better protection and an attractive appearance for many different applications. These substrates should then be enclosed in moisture barrier bio-based lamination films to prevent the development of moisture and prevent condensation and liquid leakage. The used materials meet Food and Drug Administration requirements as well as everything that is applicable to food-contact materials. The techniques result in organised and hygienic piles in line with product specification.

A tuck-top or auto-lock system makes it more resistant to loads by preventing its bottom panel from opening automatically on use and securing its contents. Coaster Box is packed with biodegradable acetate cellulose film overlaying specific window opening areas featuring shapes of coaster designs, and then hand-opened. All manufacturing batches are subjected to quality control tests, which are burst strength tests, fold endurance tests and moisture resistance tests, in the process of achieving a product standard and maintaining it.

Dimension (L + W + H) All Custom Sizes & Shapes

Quantities Minimum Order Quantity

Stock Cupboard / Rigid / Kraft / Corrugated / MOPP / PET / PE

Printing Offset / Gravure / Digital

Finishing Gloss / Matt / Soft Touch / Aqueous / Satin

Included Options Die Cutting, Gluing, Scored,Perforation

Additional Options Eco-Friendly, Recycled Boxes, Biodegradable

Proof Flat View, 3D Mock-up, Physical Sampling (On request)

Turnaround 6-8 Business Days

Shipping Flat & Assembled