How Do Poly Boxes Ensure Durability and Lightweight Handling?

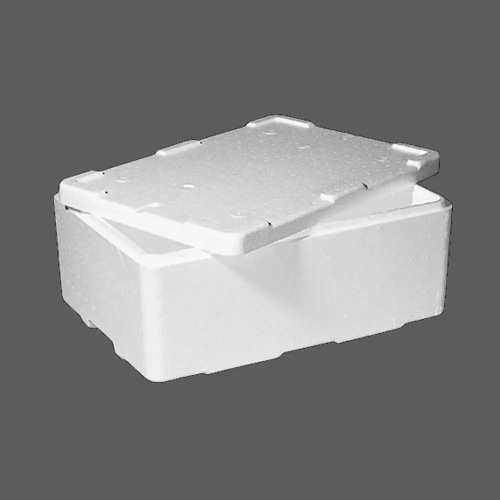

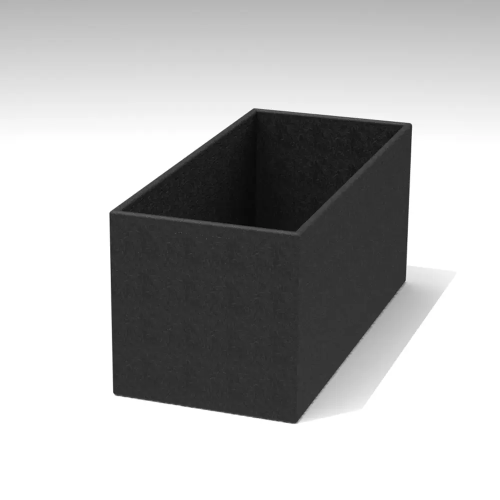

In the current medical and food industry, Poly Boxes are becoming more and more well-known due to their simplicity and ease of use. They are made of polystyrene and are an extremely lightweight and reliable solution for food delivery in a rush. Also, their strength-to-weight ratios are amazing. We make them by melting thermoplastic. It is then formed into various designs and styles. Some of them would have lids that were detached, as well as some that were connected to the bottom in a hinge design. It is also possible to add honeycomb or ribbing structures to increase their structural strength. In addition, the design could be double-walled for extra strength and sturdiness. These attributes would aid these boxes. Even with all that strength, they will be lightweight.

Strong bases and double-walled sides are common features of poly containers that permit stacking. The structure is designed to stabilise the box and prevent deformation during difficult circumstances. The lid is secured with hinges or snaps, making the box lighter regardless of the contents. There are instances where the surface is deliberately smooth to aid in gripping, as well as other instances in which the surface is left clean for ease of maintenance. Polymers don't easily break or crack, which allows poly boxes for use in humid areas with chemical substances or in changing temperatures. Since they're not made from wood or cardboard, the boxes will not become damaged or swollen, which means they can be used outdoors or indoors. Since they're light, it's easy to move them manually, and shipping them will be less costly.

What Sort of Functional Features Make Poly Boxes Ideal for Commercial Use?

The commercial usage of Poly Boxes is wide-ranging; they are utilised in numerous industries, of which the food and medical industries are among the most popular. The ability of these boxes to withstand water and other elements makes them a top option for factories and businesses where everything has to be well-organised. The structure is simple to build and can be modified to any shape. However, the box shape is the most sought-after. If used in conjunction with gel packs and ice cubes inside bags, they are perfect storage and preservation devices for medicine and food products.

The compact structure creates Poly Boxes that are ideal for carrying and easy transport. They can also be used for picnics where refrigerators powered by electricity aren't readily available, and food items need to be kept for short periods. The most significant benefit is that they don't require assembly and can be put to use at any time, from anywhere. If you have chilling gel for packaging or even ice, they are able to conserve food items for up to 24 hours in London, UK.

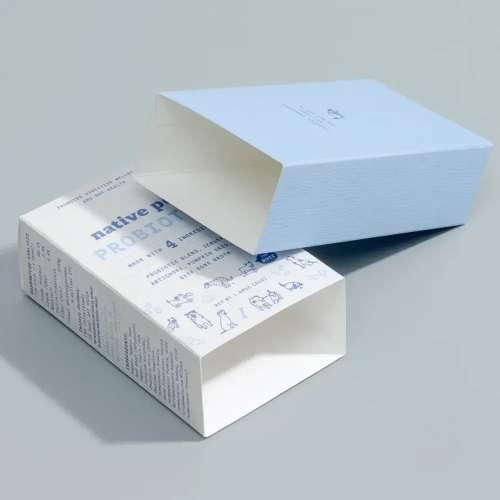

Dimension (L + W + H) All Custom Sizes & Shapes

Quantities Minimum Order Quantity

Stock Cupboard / Rigid / Kraft / Corrugated / MOPP / PET / PE

Printing Offset / Gravure / Digital

Finishing Gloss / Matt / Soft Touch / Aqueous / Satin

Included Options Die Cutting, Gluing, Scored,Perforation

Additional Options Eco-Friendly, Recycled Boxes, Biodegradable

Proof Flat View, 3D Mock-up, Physical Sampling (On request)

Turnaround 6-8 Business Days

Shipping Flat & Assembled