- Home

-

By Industry

- Acrylic Signs

- Display Stands

- Bakery Boxes

- Blister Packaging

- Candle Packaging Boxes

- Kraft Packaging Boxes

- Cosmetic Boxes

- Cereal Boxes

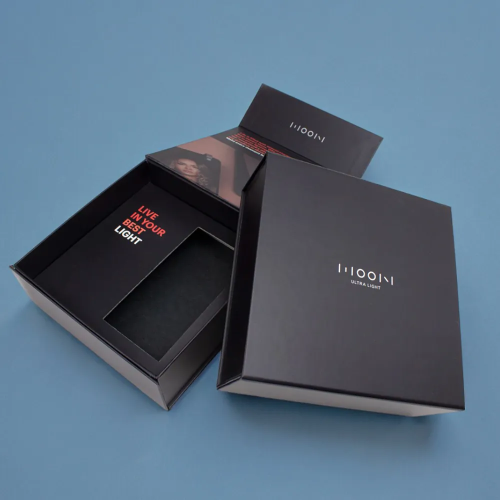

- Luxury Rigid Boxes

- Display Packaging

- Eco Friendly Boxes

- Electronic Packaging Boxes

- Pharma Packaging

- Mylar Ziplock Bags

- Food and Beverage

- Gift Boxes

- Stand Up Displays

- Metalized Boxes

- Soap Boxes

- Corrugated Shipping Boxes

- CBD Boxes

- Custom E-Liquid Boxes

- Custom Vape Packaging Boxes

- Invitation Boxes

- Retail Boxes

- Subscription Boxes

- Box Style

- Other Products

- Design Service

- Deals

- Home

-

By Industry

- Acrylic Signs

- Display Stands

- Bakery Boxes

- Blister Packaging

- Candle Packaging Boxes

- Kraft Packaging Boxes

- Cosmetic Boxes

- Cereal Boxes

- Luxury Rigid Boxes

- Display Packaging

- Eco Friendly Boxes

- Electronic Packaging Boxes

- Pharma Packaging

- Mylar Ziplock Bags

- Food and Beverage

- Gift Boxes

- Stand Up Displays

- Metalized Boxes

- Soap Boxes

- Corrugated Shipping Boxes

- CBD Boxes

- Custom E-Liquid Boxes

- Custom Vape Packaging Boxes

- Invitation Boxes

- Retail Boxes

- Subscription Boxes

- Box Style

- Other Products

- Design Service

- Deals

Free Shipping

All Across UK